Meet With Global Standards

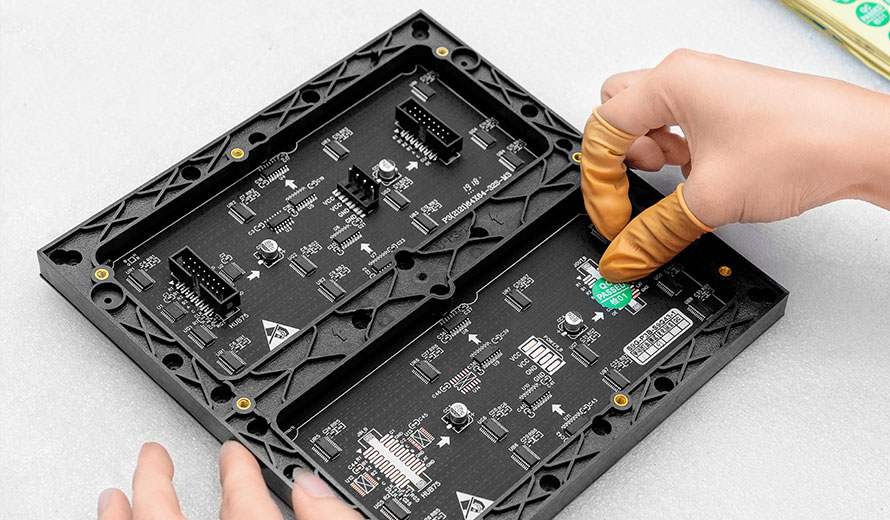

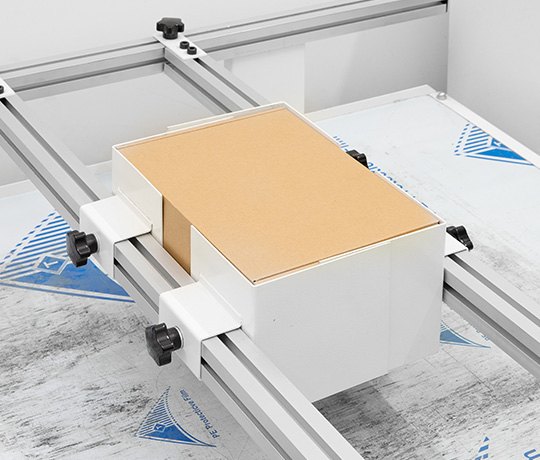

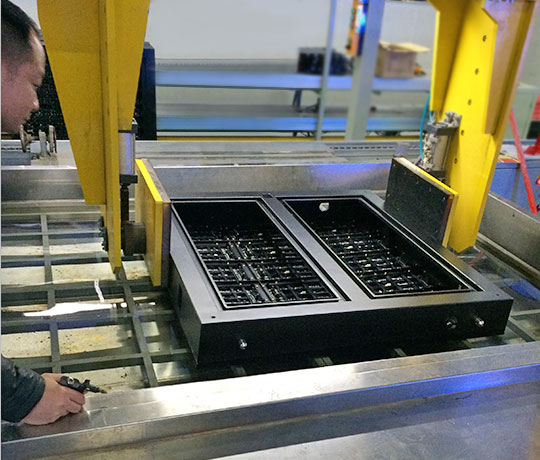

At each step of mass production, our engineer will take tests to reach a higher quality standard.

Besides regular testing, we will take additional test for displays used in different environments.

Due to our commitment to strict quality control, our display screens have reach the requirements of international certifications.