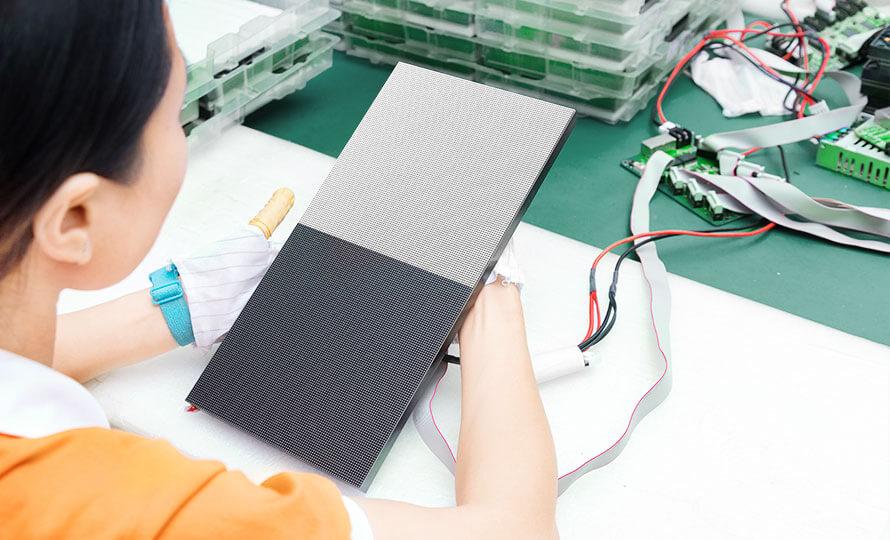

Full Material Preparation For Mass Production

After our customer approves the product design, we will make a list of material to prepare for mass production.

By doing so, we can have a better control of the delivery time and avoid delay for lack of raw material.

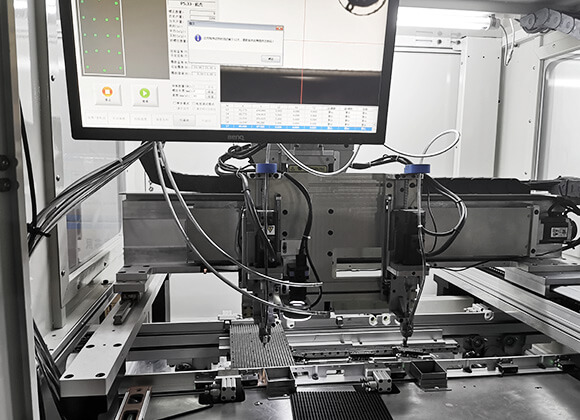

Moreover, a bulk purchase of material will lower our manufacturing cost, which will help to improve competitiveness in the market.

For special project or wholesale business, we offer customization service to let you choose raw material as needed.